It wasn't until I ran my newly finished Doripake that it clicked. This is quite possibly the ultimate setup when it comes to sheer performance, at least for our driving style and for our track layout. It was a pipe dream trying to tune my convention setup Doripake to keep up with this new breed of animal. I was like a pre-historic dinosaur in comparison, and I'm not putting that lightly... the level of performance you can gain out of your car by running a rear mounted battery on a RWD chassis is insane. At least at our track.

My initial opinions about rear weight setups was that it was going to have way too much understeer, that the rear end would snap way too hard, that it would have bad stability, and that it would be hard to catch the rear. I started out with a few tuning sessions in my driveway, about 30 minutes total, and quickly realized that everything I thought about a rear weight bias setup was wrong. I quickly came to the conclusion that I 'have' to try my car out at our local track, and get a real feel for just how good this chassis is in comparison to my other chassis. I already knew it was going to be better... but just how much better?

My rear weight bias chassis has minimal amounts of understeer, and while I admit that there is a little bit of understeer, being aggressive on the throttle makes it nearly non existent. The rear end is also firmly planted. The amount of rear end grip available while drifting is insane. You can throw your car into corners as hard as you like, and it feels like the tail will never come past the front end. I can't even begin to express how aggressive you can be with a rear weight bias setup, it's just crazy to me. You can put the pedal to the metal around most of the track, lifting occasionally to control your line, all while still maintaining the ability to run the walls. Even if I got it wrong, and was too aggressive, I could typically let off the throttle and the rear end would come back into line instead of going past the front end, allowing me to continue on drifting, laying into the power as went along.

So, basically what I learned during my visit to the track is that no matter how much I tuned my conventional setup, I was going to need to add weight to the rear diffuser in order to make it compete with this new breed of animal. Adding a ton of extra weights to a chassis is something I'm just not a fan of, but there's just no way around it, a rear weight bias chassis just offers so much grip and stability in comparison. In the exact same situation if I am pushing the absolute limits of my chassis running a conventional layout, my rear weight bias chassis is in a very comfortable zone, with performance to spare. What I've been getting at this whole time is that the rear weight bias layout currently reigns supreme in every way possible at our track, where we run a style very similar to Formula Drift. More power, more speed, more angle.

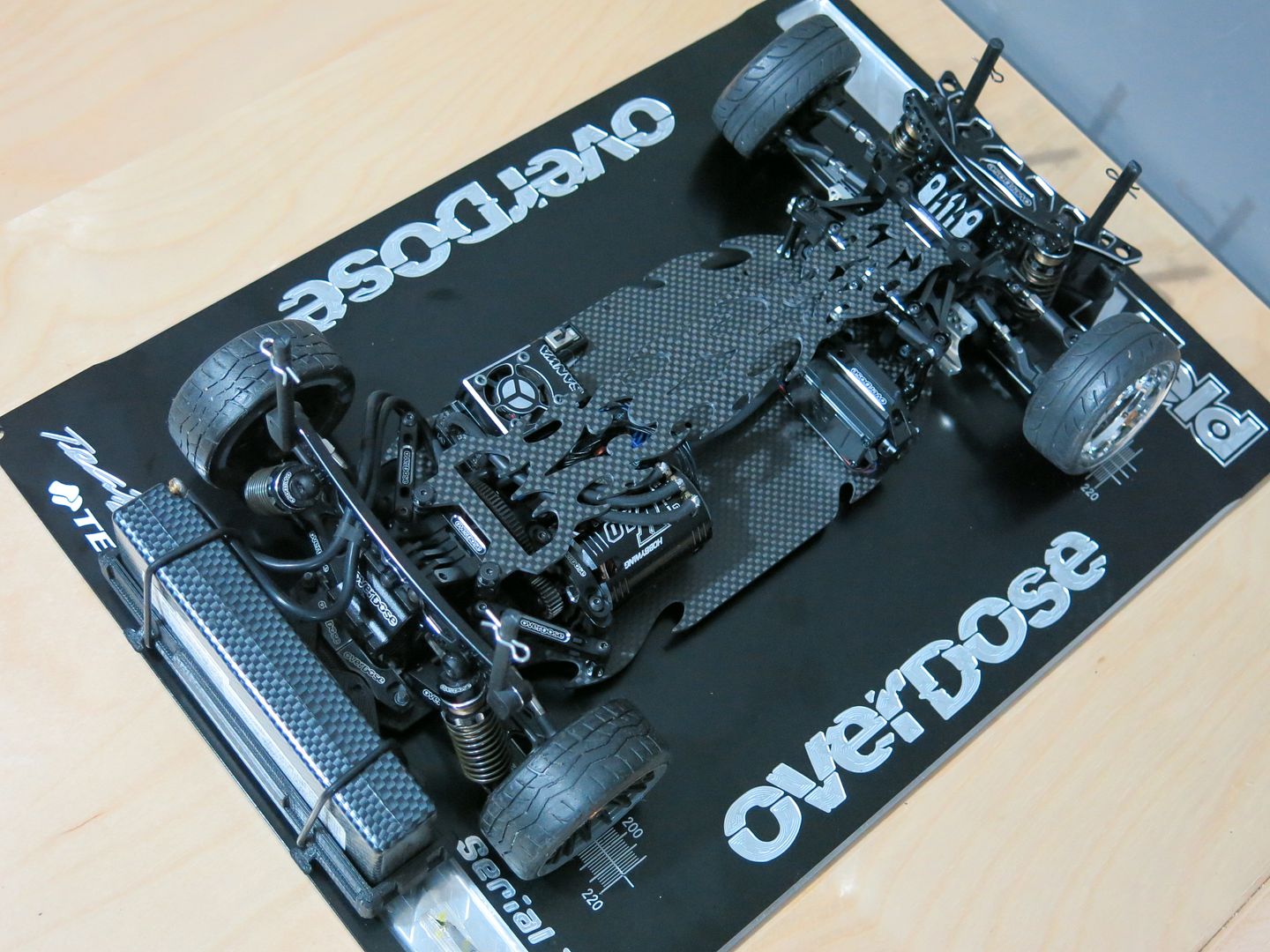

This setup might not work out as well for you as it did for me, but I firmly believe that if you're after absolute performance with your RWD chassis, a rear weight bias chassis is the way to go. I'll be going over some of my actual setup now, as I want to benchmark it, but keep in mind that what works for me isn't necessarily going to work for you. This is more so for me to be able to look back and see what my settings were, as I continue trying to develop my tune. Track surface, track style, driving style, there are just so many variables that come into play when tuning a chassis, but if you can walk away some points that help you out with your own rear weight bias setup, that's great. My setup has worked for me on asphalt, and a very slippery tile surface (very similar to polished concrete) so far. Now, let's get into the setup...

Front:

Tires: HPI Racing A-Drift

Offset: 7mm - Effective 8mm using MST brake disk wheel hubs.

Camber: -13*

Toe: 0*-0.5* (approximately)

Caster: 12* (approximately)

Ride Height: 7.5mm

Spring: Mikuni 34mm Medium Hard (PINK)

Bumper Weight: Overdose Bumper Support + 10g weights on lower wide position body post holes

Dampers: Yokomo BD7 Damper Set

Damper Piston: Yokomo 3 Hole 1.1mm Tapered Pistons

Shock Oil: 20wt Team Associated

Upper Shock Position: Lower Row, Second from the Outside

Lower Shock Position: 2nd Inner Most (WUN Type-3 Y-Arms)

Diff: 50g Weight in Front Diff Case

Other: When running a flat front tire setup, make sure at full lock, the lead wheel sits flat.

Rear:

Tires: HPI Racing T-Drift

Offset: 3mm - Effective 4mm using MST brake disk wheel hubs

Camber: 0*

Toe: 0*

Ride Height: 6.5mm

Spring: Mikuni 34mm Soft (BLUE)

Dampers: Yokomo BD7 Damper Set

Damper Piston: Yokomo 3 Hole 1.1mm Tapered Pistons

Shock Oil: 10wt Team Associated

Upper Shock Position: Lower Row, Second from the Inside

Lower Shock Position: Second Outter Most Position (Vacula Suspension Arm Set)

Diff: Yokomo Solid Spool + Stock Plastic Gear Set

Other: Oversliders Rear Full Size Lipo Mount

Drive Train:

Spur: 78t 48p

Pinion: 25t 48p

Final Drive Ratio: 7.5

Other: N/A

If you have anything you'd like to add, questions, or if you want to share your thoughts on your own attempts at building a rear weight bias chassis, feel free to leave a comment.